Every advancement that a wastewater treatment plant incorporates helps provide people with cleaner water. If you look back through history, the government didn’t address water pollution until 1948. The Clean Water Act wasn’t established until 1972. At this point, there was finally a law with clear guidelines cities and towns had to follow to prevent polluted water from going back into U.S. bodies of water. It led to construction grants for areas that wanted wastewater treatment plants. It started making our water cleaner.

Since that day, water treatment advancements keep happening. The EPA offers guidelines into the pollutants that water districts must remove and test for. If water treatment hasn’t removed enough of the bacteria, heavy metal, or chemical, the public must be notified and told not to drink the water as it’s not safe and changes must be implemented. Water shouldn’t be released to lakes, rivers, ponds, and streams and if it is authorities must be notified.

Early Wastewater Plans

In the 1850s, London’s Thames River experienced what was known as “The Great Stink of 1858.” At that time, human and animal waste was simply deposited back into the river. During a particularly hot summer, that waste caused the river, which flowed past the Houses of Parliament, to reek and politicians left for their country homes because the smell was too much. They all agreed, however, that a new system needed to be implemented. That led to the creation of London’s first sanitation system and close to 100 miles of sewers.

An ABC system was created that mixed sewer water with alum, blood, clay, magnesium, and other ingredients. This mixture moved from one settling tank to the next before being discharged to a river. The problem was that the mixture only started to clean the water. Remaining solids were treated with sulfuric acid to reduce ammonia and used as fertilizer. This process didn’t work effectively and didn’t address the foul odors of the water and solids.

Meanwhile, scientists in Massachusetts started their own experiments using sand filters to purify sewer water. The tests were successful at removing many water-borne illnesses like typhoid. Additional experiments held back in England found that if the remaining sludge was aerated to remove organics and convert any remaining ammonia to nitrite.

Advancements in Water Treatment Equipment

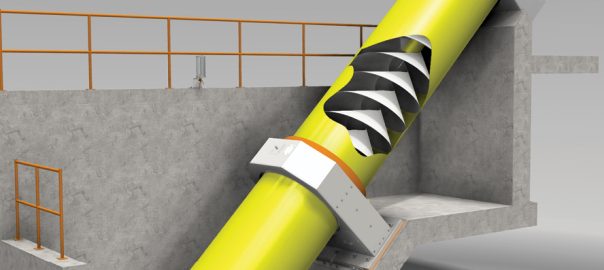

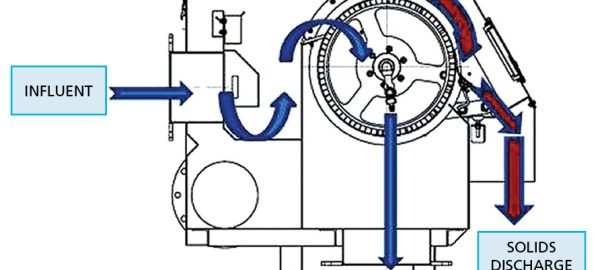

Those steps led to the process of treating wastewater. Equipment is an important part of the process. Grit removal, screening, and oxidation work together to clean water. Water enters a water treatment plant and screw pumps help move it from one area to the next. Screens remove trash and larger objects that cannot be cleaned, such as tampon applicators or plastic wrappers. Sludge settles and is removed. Remaining fluids are aerated and Biological Nutrient Removal takes place to remove nitrogen and phosphorus. What advancements are helping with cleaner water?

#1 – Solar and Wind Powered Plants

One area where water treatment technologies are seeing important advancements are with sustainability. Sustainable water treatment technologies are helping further protect the environment and water sources. Earth.org states that while Earth’s surface is 3% water, no more than 0.5% of it can be used for drinking water. Many people get their water from underground aquifers, but there’s a danger of those drying up in the next 100 years. Reusing water is critical if we are to prevent water shortages. Reusing water requires effective cleaning, which requires power. Solar can help with effective cleaning that minimizes one’s carbon footprint.

Solar-powered water treatment equipment is a trending way to deliver clean water. If you’re harnessing the power of the sun to power a water treatment plant, it reduces the emissions going into the air. You don’t have the soot and smoke from fossil fuels going into the atmosphere that end up in the rain that falls back to the ground. While a water treatment plant will clean some storm runoff, a good deal of it also ends up in rivers and lakes. The acid rain contains nitrogen oxide and sulfur dioxide, which end up in bodies of water and increase water pollution. In addition to solar-powered water treatment equipment, wind power is also being used to eliminate the need for fossil fuels.

#2 – Water Reuse

Going back to water reuse, major companies are starting to understand the importance of reusing water. Nucor Steel realized how much it could cut its water usage by recycling the water they already use and using stormwater instead of cleaned water. These changes have led to a reduction of the water used and lowered its energy bills, too. Water consumption has declined by over 200 million gallons each year with these changes. Cleaner water is saved for homes, and the company’s water needs for cooling the steel products is met by claiming stormwater run-off and rain collection.

#3 – Improved Filtration

Clay, blood, and alum were some of the first filtration materials used. Sand was next. Clean water can also be filtered with charcoal. Most recently, scientists have been using sand coated in graphite oxide to filter water. Water filtered with the graphite oxide-coated sand is five times cleaner than water filtered through sand. It’s an important tool in removing dangerous substances like mercury. They’ve also found that ground plastic bottles that are coated with cysteine are an effective filter for arsenic.

Algae grow easily in water ponds where UV rays are used to kill bacteria. That algae can be dangerous, so it must be killed and removed with chemicals like chlorine and some kind of filtration. Scientists are working on chemical-free ways to kill the algae. One is to introduce bacteria that thrive on algae and break them down into harmless materials that are easily removed through filtration.

#4 – Low-Maintenance or Maintenance-Free Equipment

There’s also an issue with a crumbling infrastructure. Cities need to look at making sure that water isn’t being lost to sewer system water main breaks. Leaks or defective water treatment equipment must be repaired or replaced to prevent water loss. Newer, modern equipment that is constantly monitored by computers and adjusted as flows increase or decrease helps with this.

Smart technology is common in homes, but it’s also being used in water treatment plants for alerts that notify engineers if there is a leak or problem in the equipment. Faster repairs prevent water loss or the release of contaminated water to lakes, rivers, and other water sources. Newer water treatment technology also reduces the need for maintenance by incorporating bearings that are never submerged below water or improving grit removal to prevent damage from abrasion.

#5 – New Equipment Improves Efficiency

Choosing the right equipment is one of the best ways to embrace cleaning water while minimizing your carbon footprint. Have you looked at upgrading your water treatment plant or business with the latest equipment and sustainable practices? Have you thought about going solar at your water treatment plant?

There is an initial cost, but the savings in terms of energy usage and efficiency make that cost worth it. If you’re spending a lot of money on maintenance or repairs, it’s time to talk about upgrading your water treatment equipment. Lakeside Equipment launched in 1928 and strives to help municipalities come up with viable ways to clean water in responsible, environmentally-friendly ways. Call us to discuss your needs for high-quality, cost-effective water treatment equipment.