To build an industrial sewage treatment plant, you first must address what industrial sewage is. It’s wastewater produced in an industrial setting.

Water treatment plants handle different types of wastewater. You have domestic sewage that contains residential toilet water and gray water (water from showers, baths, washing machines, etc.) from houses and apartments. There’s storm sewage that is the rainwater and snowmelt that goes into drains found on the street. Finally, you have industrial sewage, which is the used water from manufacturing plants and factories.

Industrial sewage often contains higher levels of chemicals and pollutants than domestic sewage or storm runoff. It can be the wastewater created while manufacturing batteries, refining petroleum, and making paper in paper mills. This type of wastewater must be handled appropriately to ensure that it’s clean enough to send back to bodies of water or be reused in the businesses that use the water.

Industrial wastewater often contains heavy metals, food waste, inorganic materials like rubber and metal shavings, microplastics, radionuclides, and many toxins. For this reason, you must treat it appropriately. None of those should be returning to drinking water storage tanks, rivers, lakes, etc. The treatment plant must be designed to treat industrial sewage.

Many sewage treatment plants in residential settings are ill-equipped to handle industrial wastewater. It makes it harder to properly treat the water and damages equipment, leading to expensive repairs and downtime. An industrial business owner has to stop and think of the impact on the local wastewater district. As a result, companies consider building their own onsite treatment plants to pretreat water before it goes to the sewers.

The Steps Involved in Industrial Sewage Treatment

As water leaves your machines and buildings, where it goes depends on your setup. You may need to build an onsite industrial sewage treatment plant. If your city wants you to do the first stages of treatment before releasing your wastewater to the sewers, it’s important to understand what equipment is needed.

You might prefer to put in a small wastewater treatment plant on your grounds and reuse the water. That lowers your water bill and helps the environment. Denmark’s Carlsberg Brewery came up with a plan to use at least 90% of the wastewater the brewery uses and to create biogas to produce energy the plant needs. The goal is to reach zero water waste within the decade. It’s an ambitious, respectful goal that starts with an industrial wastewater system that covers these steps.

#1 – Screening

As wastewater enters a wastewater treatment plant, the solids must be removed. If they’re left in, they can clog lines and damage equipment in downstream processes. Don’t let your plant’s efficiency tank because of damage or clogs.

With the use of open screw pumps, you don’t need pre-screening. Move the wastewater into the open screw pumps for screening and grit removal. Once there, additional screw pumps keep the sewage flowing to primary clarification tanks.

Lakeside Equipment’s Raptor equipment screens and washes solids. From there, they are compacted and dewatered. As they’re made from stainless steel, they’re ideal for use in industrial sewage processes. Choose from rotary strainer screens, rake bar screens, rotating drums, micro strainers, and fine screens. This allows you to choose the best screen for the job.

#2 – Primary Clarification and Grit Removal

Once the wastewater is screened, it goes through the primary clarification process. Some plants also need to install grit removal systems. Clarification moves the wastewater and helps remove any additional solids that have settled in the wastewater.

You might choose a peripheral feed with a surface skimmer that pushes floating solids into a trough where the solids are removed. A Spiraflo clarifier holds solids in a sludge blanket that travels towards a center hopper for removal. Lakeside also has the Spiravac that pushes the solids to the sides where they get trapped between a skirt and wall and end up falling into a settling area.

Not all industrial wastewater treatment plants need grit removal systems, but some do. These systems remove fine grit like coffee grounds, bone fragments, eggshells, etc. You’d want to put in grit collection systems if you run a meat processing plant, a plastic extrusion company where microplastics make their way into the wastewater. Another example is a chicken farm where you’ll have seeds and eggshells getting into the wastewater.

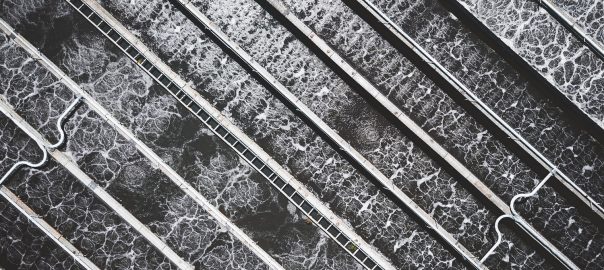

#3 – Aeration

Aeration stirs up the wastewater to add oxygen to the mix. The oxygen feeds the microorganisms that help digest some of the contaminants remaining in wastewater. You don’t want any small particles of waste material to settle at this point. By continually stirring up the water, nothing can settle.

Magna Rotor Aerators have fiberglass rotor covers to eliminate spray. That will keep odors down and protect workers from wastewater droplets. Plus, the covers can trap heat from escaping in the cooler months. The aeration blades are stainless steel, which helps prevent corrosion.

#4 – Secondary Clarification

The water is getting pretty clean at this point, so wastewater goes into secondary clarification. The process is the same as you’d find in the primary clarification process. The remaining particles are negatively charged after the other processes. They’ll bond, which makes it easy for the clarifiers to remove these remaining particles.

#5 – Disinfection

Now it’s time to disinfect the treated water. Industrial wastewater carries a lot of contaminants like lead, chemical cleaning agents, cyanides, etc. Disinfection is required to remove them. UV disinfection is one option. Using UV lighting is an environmentally friendly method for disinfection without relying on chemicals like chlorine.

Chlorine and chlorine products are the first choice in industrial wastewater treatment. In addition to disinfecting the wastewater, chlorine also removes ammonia, kills any remaining organic materials, and oxidizes iron, hydrogen sulfide, manganese, and organic matter. Chlorine is cost-effective, but it has to be removed before the wastewater moves back into a lake, stream, or other body of water.

Other Wastewater Treatment Equipment That Benefits Your Plant

Are there other wastewater equipment and tools you should incorporate in your design? A SharpBNR is a process control system that allows you to fine-tune your equipment along the way. You can monitor readings and adjust aeration as needed. With this system, you maximize efficiency. If you have a SCADA system, you can monitor your wastewater treatment processes from anywhere.

The type of equipment you choose will lower your operating costs and effectively clean the water. Calhoun, Georgia, is home to several manufacturers of flooring, which leads to very corrosive wastewater. Lakeside Equipment helped the city build a sewage treatment plant designed for industrial wastewater by using open screw pumps with stainless steel tubes that withstand the corrosive materials.

Manufacturing plants, food processing companies, and other factories have two goals when it comes to industrial wastewater treatment. They want energy-saving designs that keep costs low, but they also want a water treatment system that properly cleans the water. Meet your budgetary goals and get a system that does exactly what you expect. Give us a call to discuss your industrial sewage treatment plant. Our team of specialists is happy to help design a system to your specifications that’s going to last.